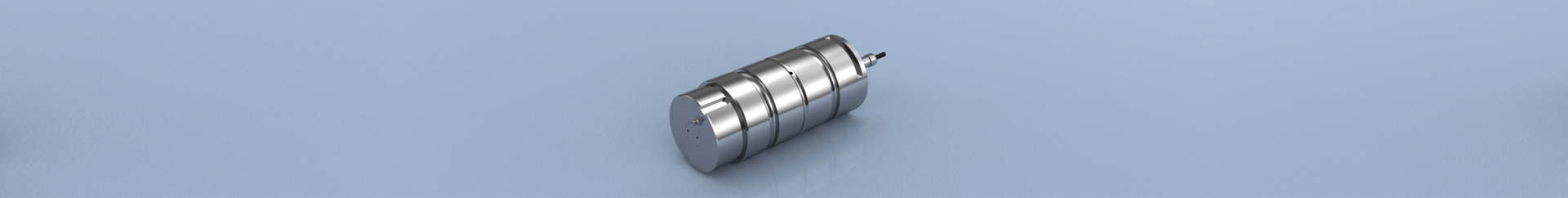

LMP

- De 500 kgs a 1500 toneladas

- Construcción de acero inoxidable

- Sellado al medio ambiente según IP67

Los puertos y las terminales de todo el mundo se enfrentan al reto de lidiar con buques y cruceros cada vez más grandes. Además, debido al cambio climático, las condiciones meteorológicas más extremas están repercutiendo en los niveles de tensión a los que están sometidos los cabos de amarre. El fuerte viento, las olas y las corrientes hacen que, incluso cuando están atracados, los barcos estén en constante movimiento. Esto significa que la tensión ejercida por los cabos de amarre cambia constantemente, lo que contribuye a la fatiga de los materiales y reduce su vida útil. Además, si una o varias líneas de amarre experimentan niveles de tensión más elevados que otras, existe un riesgo real de que la línea de amarre se rompa, lo que puede provocar daños al muelle y al personal.

Para garantizar que un buque permanezca atracado de forma segura, la tensión de cada cabo de amarre debe estar sometida a la misma carga o tensión, o lo más cercana posible. Esto puede lograrse mediante la instalación de un sistema de medición de la tensión de amarre, que supervisa continuamente las cargas de cada cabo de amarre, de modo que cualquier caso de sobrecarga o subcarga pueda identificarse inmediatamente. Los operadores portuarios pueden entonces alertar a los capitanes de los buques para que puedan tomar rápidamente medidas correctivas para redistribuir uniformemente las cargas de las líneas de amarre.

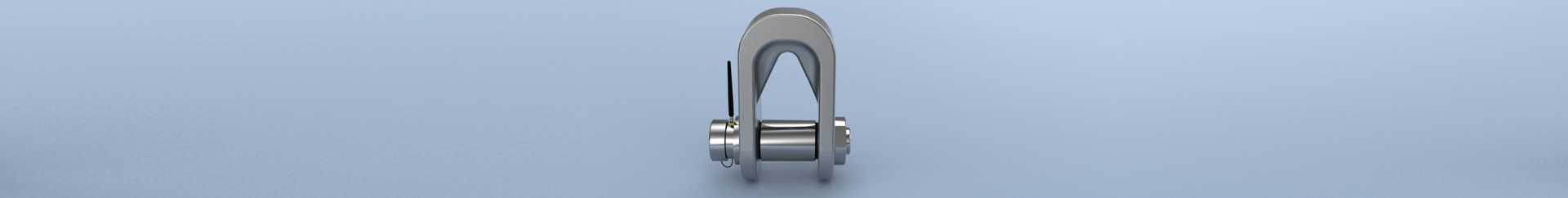

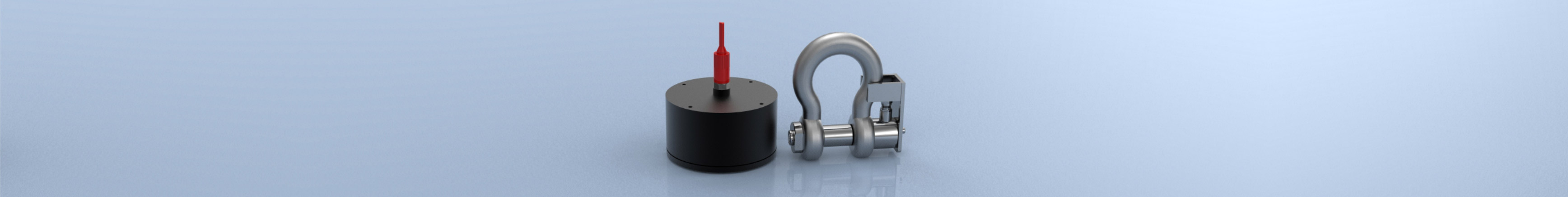

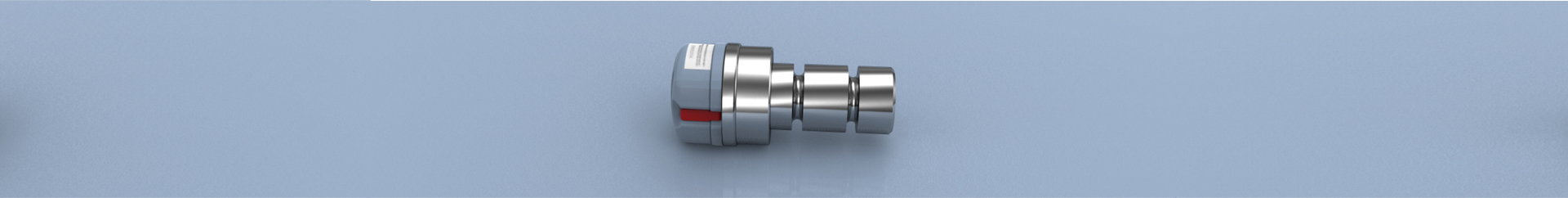

Los sistemas de medición de amarre que suministra LCM Systems utilizan clavijas de medición de carga instaladas en ganchos de amarre de liberación rápidao Celda de Carga Grillete/Dinamómetro Electrónico de Tracción que se instalan en la estructura de la línea de amarre y se fijan a las instalaciones de amarre existentes en el puerto. Los datos de medición de la carga proporcionados se introducen normalmente en un sistema PLC, pero puede proporcionarse una lectura separada cuando sea necesario (normalmente en puertos más pequeños). Esto también puede incluir alarmas que se activan en caso de situaciones de sobrecarga.

A continuación encontrará una selección de algunos de nuestros estándares más populares Células de carga y basados en sensores Productos utilizados para la medición de la tensión de amarre Aplicaciones

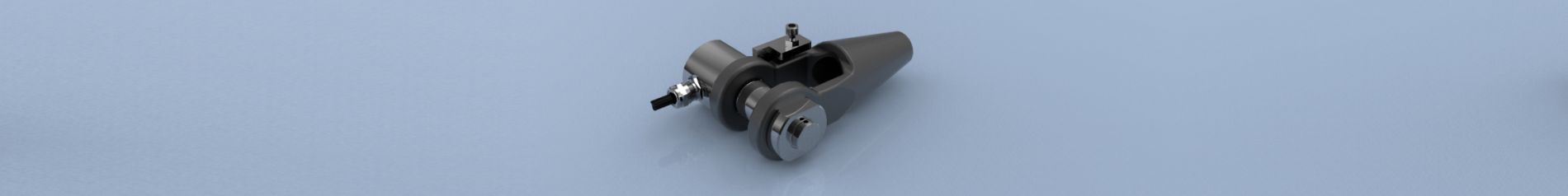

LMP

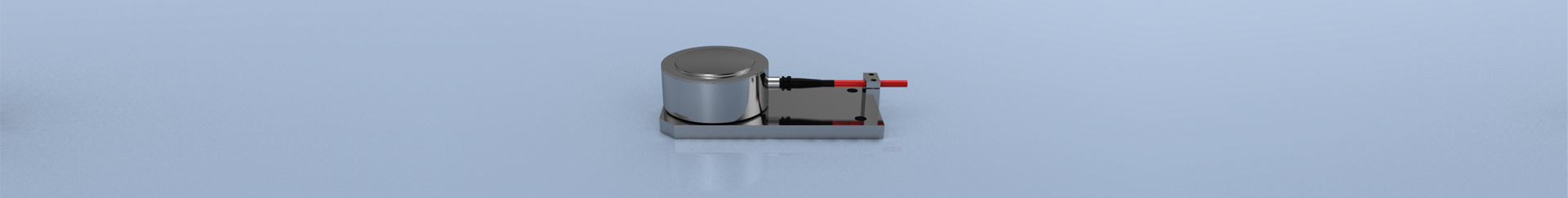

LPB

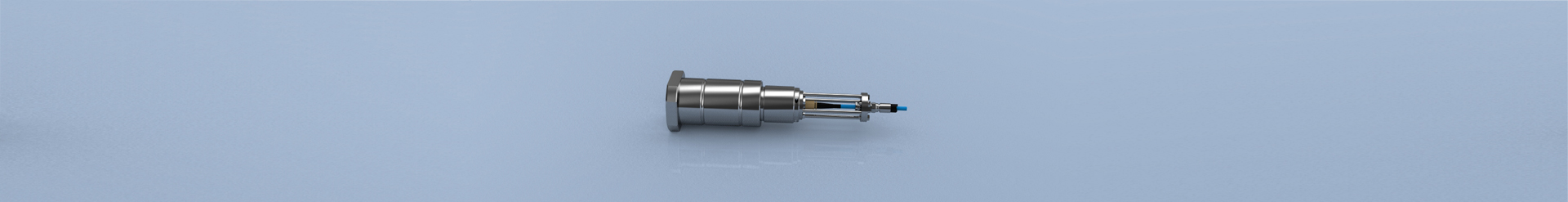

LPC

SHK-B

TELSHACK-B-HL

TLL

WLL

A continuación encontrará una selección de nuestros estándares más populares Instrumentación Productos utilizados para la medición de la tensión de amarre Aplicaciones

DIS-323AL/SS ATEX

LCA20

LD-STRAIN

PMD-STRAIN

SGA

T24-ACM

T24-HS-LS

TR150

X24-ACMi-SA

A continuación se presenta una selección de algunas de nuestras soluciones de productos Diseño a Medida utilizadas para la medición de la tensión de amarre Aplicaciones

LCM1410

LCM1791

LCM3064

LCM3511

LCM3782

LCM4487

LCM4550

LCM4570

LCM4823

Aplicaciones ¿Qué medidas de tensión de amarre ha satisfecho ya LCM Systems ?

Por favor, revise algunas de las noticias recientes relacionadas con la Medición de la Tensión de Amarre Células de carga, Bulones de Carga y el asociado Instrumentación que hemos suministrado a nuestra base de clientes. Éstas ayudarán a demostrar la experiencia que tenemos en la búsqueda de soluciones para nuestros clientes, además de la oferta de productos estándar disponibles para esta aplicación.

15 de agosto de 2025

Acuicultura - Proteja sus existencias

Las tormentas y las fuertes corrientes son una amenaza real para las jaulas de acuicultura ancladas. Qué pasaría si pudiera controlar de forma proactiva la tensión de la línea de anclaje y evitar peligrosas roturas y posibles escapes de peces?

11 de julio de 2025

150te Celda de Carga Grillete para parque eólico marino

Acabamos de enviar 8 grilletes de control de carga de 150 toneladas que hemos diseñado y fabricado utilizando grilletes de eslinga Royal Van Beest (Green Pin®). Se instalarán en un parque eólico marino del Mar del Norte.

11 de abril de 2025

400te Celda de Carga Grillete for FSO Mooring Line Monitoring

Recientemente hemos enviado dos 400te Celda de Carga Grillete a un cliente con sede en el Reino Unido que se especializa en sistemas de amarre de petróleo y gas en alta mar.

4 de abril de 2025

55te Sumergible Celda de Carga Grillete

Estas Celda de Carga Grillete sumergibles de 55 toneladas se han suministrado a un cliente del Reino Unido para la supervisión de la carga de los cabos de amarre en una plataforma flotante de nuevo diseño para amarres submarinos en aguas profundas.

19 de abril de 2024

Sumergible de 9,5 toneladas Celda de Carga Grillete

Estas cuatro Celda de Carga Grillete de 9,5 toneladas han sido encargadas por una empresa canadiense y se utilizarán para controlar la tensión en los cabos de amarre de los dispositivos de desalinización impulsados por las olas.

23 de febrero de 2024

Registro de datos sumergible de 17 toneladas Dinamómetro Electrónico de Tracción

Recientemente hemos suministrado este sumergible de 17 toneladas de capacidad nominal Dinamómetro Electrónico de Tracción que incorpora un registrador de datos a una empresa española. Se instalará a 30 metros bajo el mar en la línea de amarre de una boya flotante.

6 de octubre de 2023

4,75te Celda de Carga Grillete para un proyecto de investigación submarina

Estos grilletes sumergibles, con una capacidad nominal de 4,75 toneladas, han sido adquiridos por la Agencia Científica Australiana y se utilizarán en un proyecto de investigación que requiere su despliegue durante 12 meses bajo el mar.

2 de junio de 2023

200te Bulones de Carga para la monitorización del cabo de amarre de la boya CALM

Este Bulones de Carga de 200 toneladas, fabricado para un importante proveedor británico de equipos de control y supervisión remota de boyas CALM, se instalará en un Celda de Carga Grillete y se utilizará para supervisar la carga de los cabos de amarre en una boya de amarre de un solo punto.

20 de enero de 2023

85te ATEX/IECEx Celda de Carga Grillete para aplicaciones de amarre

Embalados y listos para su envío están estos 85te con certificación ATEX/IECEx Celda de Carga Grillete, que se utilizarán para supervisar las cargas en las líneas de amarre de una FSRU (Unidad flotante de almacenamiento y regasificación).

29 de julio de 2022

25te Sumergible Celda de Carga Grillete

Este 25te submarino Celda de Carga Grillete ha sido enviado a una empresa británica de turbinas mareomotrices. A petición suya, se diseñó sin componentes de acero inoxidable para minimizar la corrosión.

7 de julio de 2022

Grillete 285te Bulones de Carga

Estos 285te Bulones de Carga se instalarán en Celda de Carga Grillete y se utilizarán para controlar la carga de los cabos de amarre en una boya de amarre de un solo punto.

21 de abril de 2022

Sumergible Dinamómetro Electrónico de Traccióncon registro de datos

Este Dinamómetro Electrónico de Tracciónde acero inoxidable de 8 toneladas se ha fabricado para una empresa de piscicultura de Nueva Zelanda, y se utilizará para controlar la tensión de los cabos de amarre de grandes tanques flotantes de peces en alta mar.

14 de abril de 2022

Grillete de 1000 toneladas Bulones de Carga

Enviados esta semana y de camino a los EE.UU. están estos dos pernos de 1.000 toneladas Celda de Carga Grillete.

2 de noviembre de 2021

Sumergible anular 8000N Células de carga

Recientemente hemos suministrado este 8000N Células de carga para su despliegue a 80 metros bajo el mar para medir la tensión en la línea de amarre de un sistema de generación de energía de las olas en alta mar.

14 de mayo de 2021

750 toneladas Bulones de Carga para el control de la carga de anclaje

Recientemente hemos enviado un pedido de 40 ATEX/IECEx Bulones de Carga, cada uno de ellos con una capacidad de 750 toneladas, con un diámetro de 320 mm y una longitud de 910 mm.

3 de julio de 2020

55 toneladas inalámbricas Celda de Carga Grillete

Celda de Carga GrilleteEl jueves de la semana pasada recibimos un pedido de cinco de nuestras TELSHACK-B inalámbricas de 55 toneladas, que se necesitaban urgentemente para un proyecto en el Golfo de México.

5 de junio de 2020

ATEX/IECEx Bulones de Carga para el buque de producción FLNG

Ya están listos para su envío estos certificados ATEX/IECEx Bulones de Carga.

22 de mayo de 2020

50kN Sumergible Bulones de Carga

Esta semana se enviaron a un cliente de Canadá estos dos X/Y 50kN de acero inoxidable Bulones de Carga.

21 de febrero de 2020

120te Bulones de Carga para el control de la carga de los bolardos de amarre

A menudo se nos pide que suministremos Bulones de Carga para adaptarnos a la página web del cliente Celda de Carga Grillete de diversos fabricantes.

13 de diciembre de 2019

Telemetría 400te Celda de Carga Grillete

Fabricados para un cliente estadounidense y enviados esta semana fueron dos de nuestras 400 toneladas de telemetría Celda de Carga Grillete.

11 de octubre de 2019

200te inalámbrico y cableado Celda de Carga Grillete

De camino a un proveedor de sistemas de producción de petróleo y gas en los Emiratos Árabes Unidos se encuentran estos dos Celda de Carga Grillete de 200te que pueden utilizarse de forma inalámbrica o por cable.

4 de octubre de 2019

100te Bulones de Carga para aplicación de amarre

El primer lote de 6 Bulones de Carga se ha enviado a un importante fabricante de equipos de amarre, y se instalará en ganchos de amarre de liberación rápida para proporcionar un control de la carga de las líneas de amarre.

12 de julio de 2019

Tensión de 10kN Células de carga

Recientemente se ha fabricado para un cliente del Reino Unido que trabaja en el sector de las energías renovables en alta mar esta tensión nominal de 10kN Células de carga.

28 de marzo de 2019

200te ATEX Celda de Carga Grillete

Esta semana se enviaron estos cuatro 200te ATEX Celda de Carga Grillete para una aplicación de monitorización de la carga de una boya de amarre.

9 de noviembre de 2018

500 toneladas X/Y Bulones de Carga para aplicación de amarre

Listo para ser entregado a nuestro cliente es este 500kN X/Y bidireccional Bulones de Carga.

7 de septiembre de 2018

600te sumergible de doble puente Bulones de Carga

Calibrados hoy y listos para su envío están estos dos 600te de doble puente, sumergibles Bulones de Carga.

3 de agosto de 2018

1000te Telemetría Celda de Carga Grillete para el buque de colocación de tuberías en alta mar

Recientemente hemos enviado un equipo de telemetría de 1.000 toneladas Celda de Carga Grillete, que ya está de camino a un importante proveedor de servicios de petróleo y gas, donde se utilizará en uno de sus buques de colocación de tuberías en alta mar.

1 de junio de 2018

350te ATEX Bulones de Carga para aplicaciones de petróleo y gas

Sobre para salir de la fábrica son estos 350te ATEX Bulones de Carga para Chevron, que se instalarán en una de sus terminales de petróleo y gas.

27 de abril de 2018

Bulones de Carga para el control de la carga de amarre en una boya SPM

Ya están listos para su envío estos equipos con certificación ATEX de Zona 1 y 2 Bulones de Carga, que se enviarán a una importante empresa de construcción naval y de la industria pesada en Oriente Medio.

29 de septiembre de 2017

10 x 900kN Bulones de Carga para cabrestantes de amarre marinos

Hoy salen de la fábrica 10 x 900kN Bulones de Carga para un cliente europeo especializado en el diseño de sistemas de cabrestantes y equipos de cubierta para la industria naval y de alta mar.